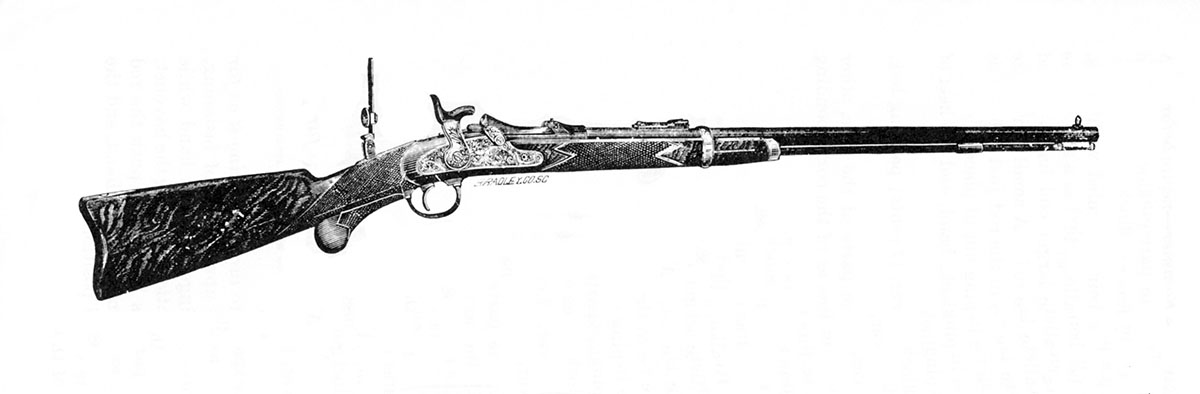

Trapdoor Barrel Specifications

feature By: William P. Mapoles and Mike Benton | March, 22

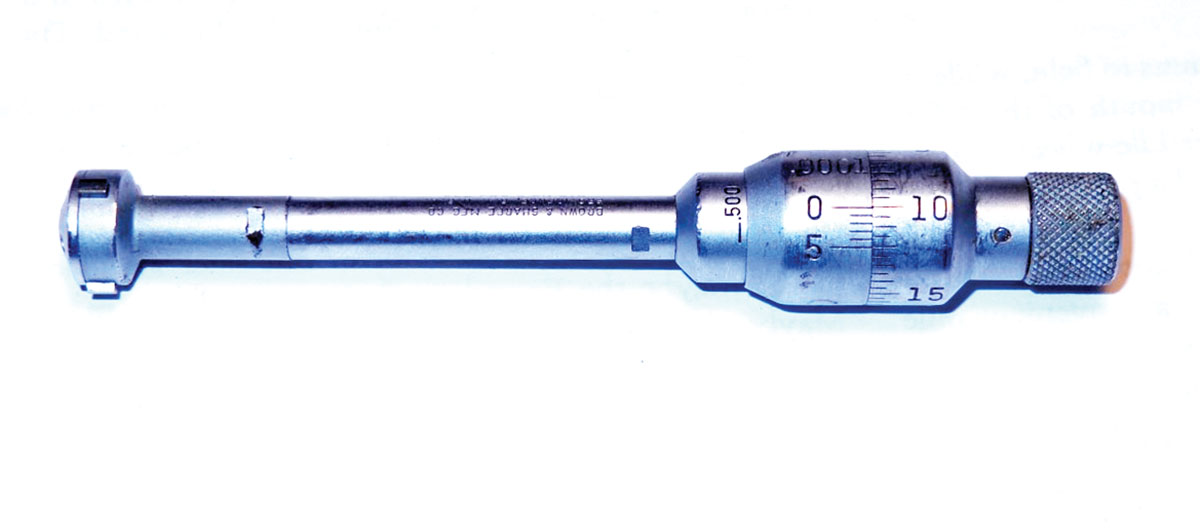

The interior of the three-groove barrel in a Trapdoor is very hard to measure. However, we are fortunate enough to have the proper tools; namely, two special micrometers designed for this kind of situation. They take internal measurements at three points within the barrel, which coincide precisely with the three grooves. The micrometers are made by Brown & Sharpe, with one being ideal for the .45-70, and the other perfect for the .50-70. The first has a measurement range from .425 to .500 inch in .0001-inch increments, while the other goes from .500 to .600 inch in .0002-inch increments. Both are long enough so a gun owner can get deep into the barrel past any ramrod wear at the muzzle from cleaning.

The reason we undertook this project was to satisfy ourselves on the impression we had gained over the years that there was no real standard for groove diameter, despite Springfield Armory’s published dimensions, and that the average groove diameter was considerably larger than the nominal. In a lifetime of shooting Trapdoors, the two of us have owned about 15 of them, of all models, and we have measured well over 100. Normally, we only measure barrels in excellent condition, because we are always searching for a great shooter, within specification, so we don’t bother measuring those with lots of wear. We never go to a gun show without these micrometers.

In .45 caliber, we have found only one which measured .459 inch, with a few coming in at .460 inch. The average, however, is .462 inch, with .463 also common. The largest we’ve ever found was .468 inch, with a number running between .466 and .467 inch. Obviously, well-worn barrels could be even larger.

We also had the opportunity to measure a number of excellent Officers Model rifles, and we naturally assumed that these custom-made, expensive carbines would certainly have tighter barrel specifications. We were wrong – they were just as sloppy as the standard issue Trapdoors, with the average being .462 inch.

Often, we can’t load sufficiently oversized bullets into the cartridges and still chamber them in rifles with groove diameters of about .462 and larger. The chamber diameter is often too small, and this is a well-known phenomenon to readers of this magazine.

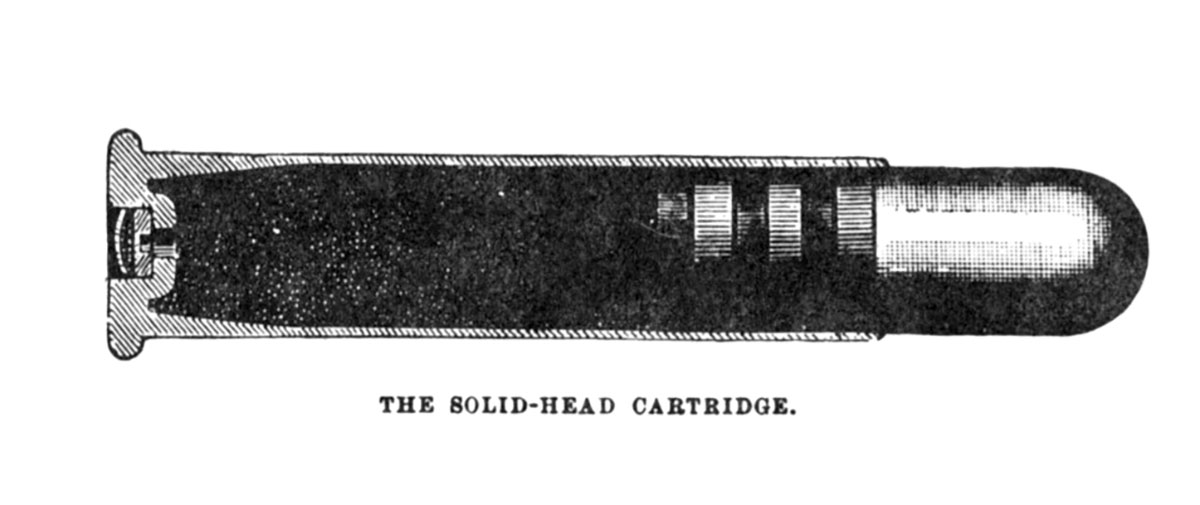

So how did the Army deal with this problem? We know from original bullets recovered at local forts, that the Army developed a fairly soft, 405-grain bullet with a hollowbase, similar to a Civil War Minié ball, which would expand upon firing to fill the rifling. Then in the 1880s, came the 500-grain bullet with a solid base, which would “bump-up” into the rifling somewhat. However, our experience shows that neither of these bullets worked very well in those guns with grossly oversized grooves.

In .50-70 caliber, groove diameters are all over the map, with almost none measuring .515 inch. The average runs between .520 and .522 inch, with some as high as .526 inch. We have found that a .520 bullet of soft lead often does the trick.

Many newcomers to our sport buy Trapdoors because they are plentiful and relatively cheap. There is also the “romantic flair” of the Wild West. Often, people get sorely disappointed with their new acquisition and just give up, especially if they are using smokeless powder and commercial hard-cast bullets of .458 inch. This combination does not “bump-up” sufficiently, resulting in gas cutting and leading, which makes things even worse. We see it at our gun club several times every year. Therefore, if you spot a new guy with a Springfield Trapdoor, please take them under your wing, acquaint them with the groove diameter data from this article, and recommend the book mentioned below. With your help, some black powder, an oversized neck expander, and perhaps the Lee hollowbase bullet mould, they can usually turn their new toy into a good shooter.

Note: “Loading Cartridges for the Original .45-70 Springfield Rifle” by J.S. and Pat Wolf, Third Edition is available at: Wolf’s Western Traders, Phone 985-882-3401. Everyone who shoots a Trapdoor should have this book, because it provides lots of critical information for accuracy.