A Black Powder Cartridge

Neck Tension Test

feature By: Rick Moritz | June, 22

TEST PLAN

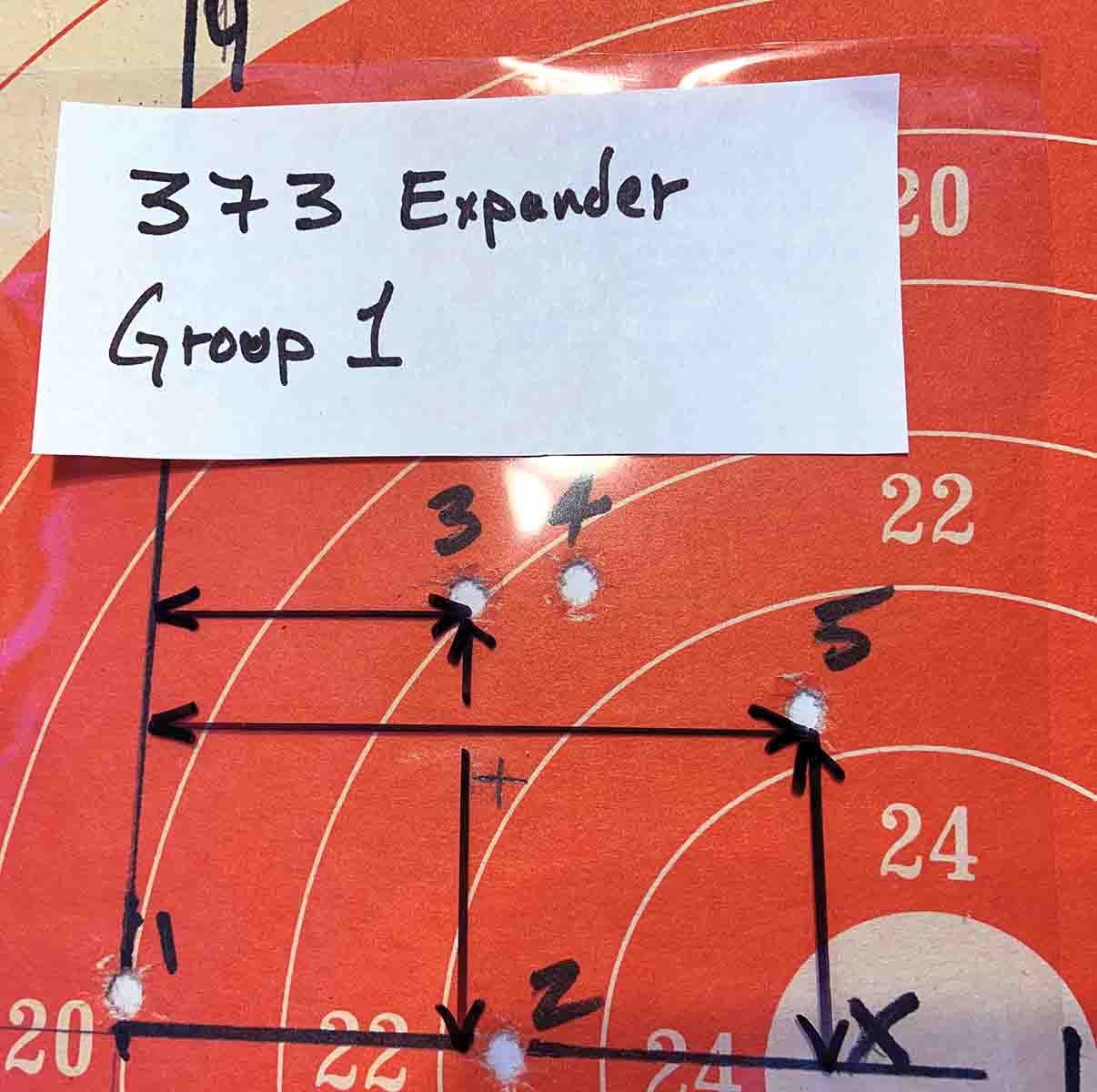

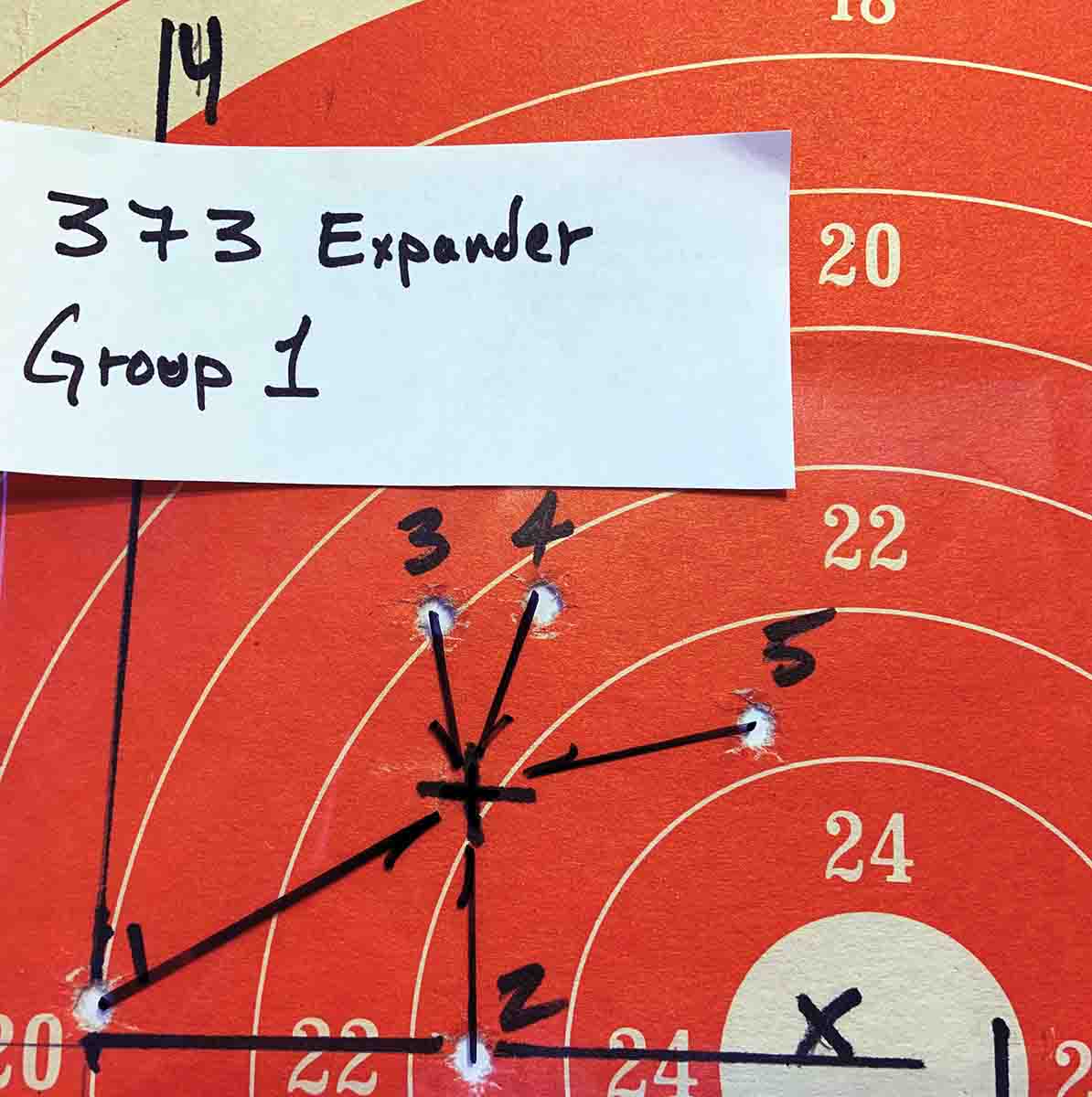

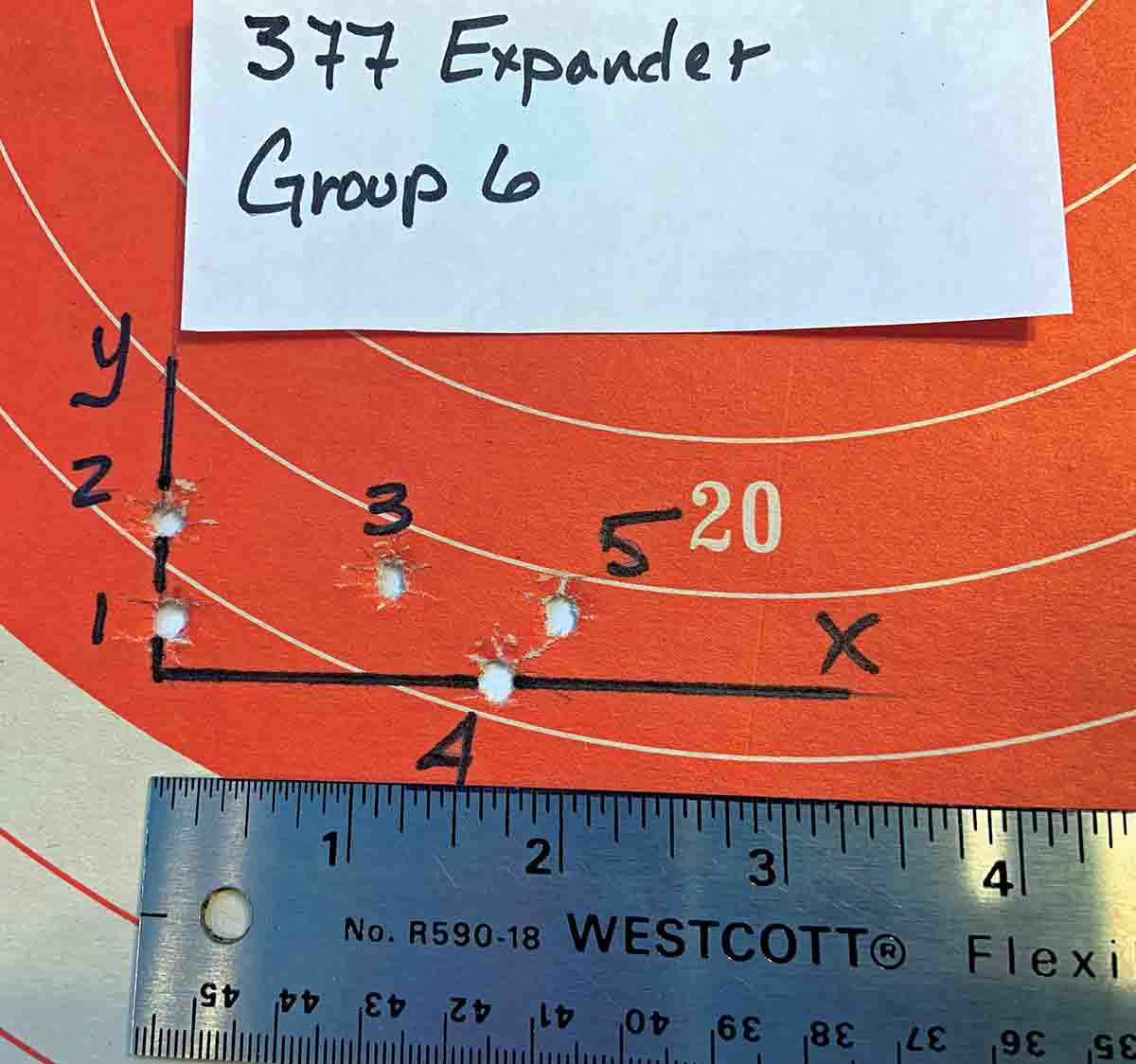

The plan was to use four different expander diameters to test for any accuracy difference between the resulting neck tension. Expander diameters used were .373, .375, .376 and .377 inch. Gauge pins were modified and used as expanders. These were rounded and tapered on one end and held in a bullet puller to effect expansion.

Gauge pins can be purchased relatively cheaply. The selected pins were Z plus. These pins are approximately three ten-thousands of an inch over the stated diameter. As a point of reference, the final case inside diameter was consistently .001 inch less than the pin expander diameter. If an expander with the same diameter as the bullet is used to expand the case, it will spring back enough to hold the bullet firmly. The final inside diameters tested were: .372, .374, .375 and .376 inch. The 20:1 (Pb:Sn) 367-grain Money bullet was used for all the tests and has a base diameter of .376 inches. All case neck inside diameters were double-checked with gauge pins before loading. For clarity, the final neck tension for the four tests was four, two, one and zero thousandths of an inch. This is based upon the final expanded inside dimension of the case and the outside dimension of the Money bullet basebands.

A total of 35 cartridges, plus foulers, were loaded for each neck tension, resulting in a total of 140 rounds for the planned test. The hypothesis for the test was there will be no difference in accuracy between the four different neck tensions. To avoid shooting the four tests under dissimilar conditions, I decided to shoot the four different neck tensions as a series of five-shot groups. Rather than basing the analysis on group size, which would only represent the two worst shots, I decided to use a variation of the mean radius method for the analysis. Five-shot group sizes are included in the analysis section for interest. Julian Hatcher in Hatchers Notebook and JS and Pat Wolf in Loading Cartridges for the Original .45-70 Springfield Rifle and Carbine both present a good description of the mean radius method.

LOADING DETAILS

All shooting was completed using a CPA Stevens 44½ chambered in .38-50 Remington Hepburn. The rifle has a Green Mountain 12-twist barrel with nominal barrel dimensions of .376 bore and .367 groove. Hornady brass was used for the testing. The brass was fireformed from new Hornady .30-40 Krag brass using a small charge of pistol powder and Cream of Wheat filler capped with a wax wad. After forming, all cases were subsequently fired with black powder to ensure full expansion. The cases were then trimmed to 2.250 inches, sized, cleaned, annealed, flared and expanded to the appropriate diameter. The Hornady brass was found to be 13 grains heavier than my normal Winchester brass. This resulted in 2.5 grains less powder capacity. Based upon a brass density of 8.73 g/cc and the bulk density of black powder (1.72 – 1.8 g/cc) the lost capacity is equivalent to .19 grains of black powder per grain of brass. The neck thickness after fireforming was extremely uniform and the Hornady brass is of very high quality. I obtained far better brass by this fireforming method than I have in the past using a series of four expanders to open the case neck.

A 367-grain Money bullet cast from my 20:1 (Pb: Sn) alloy was used for all the tests. Each cartridge was loaded with a charge of 57 grains of 2Fg Swiss with a CCI Large Pistol primer and a .090-inch HDPE over powder wad. Before seating the bullet, all powder charges were compressed .190 inch. The overall cartridge length was 3.340 inches which is .030 inches proud of being fully seated in the chamber. Due to the taper of the bullet, the cartridges can be fully seated with strong thumb pressure, alternatively, the Stevens action upon closing easily seats the cartridges.

All cartridges were kept in separate containers based on the expander diameter used and were color coded with a felt-tip marker. The test targets were also labeled with the expander diameter, large enough to be read with the spotting scope from 200 yards to ensure keeping the correct cartridges on the correct target.

The rifle and bullet combination has been a very reliable performer in the past, so it was selected for this extensive test. All shooting was done with an MVA six-power scope with DZ mounts.

ANALYSIS

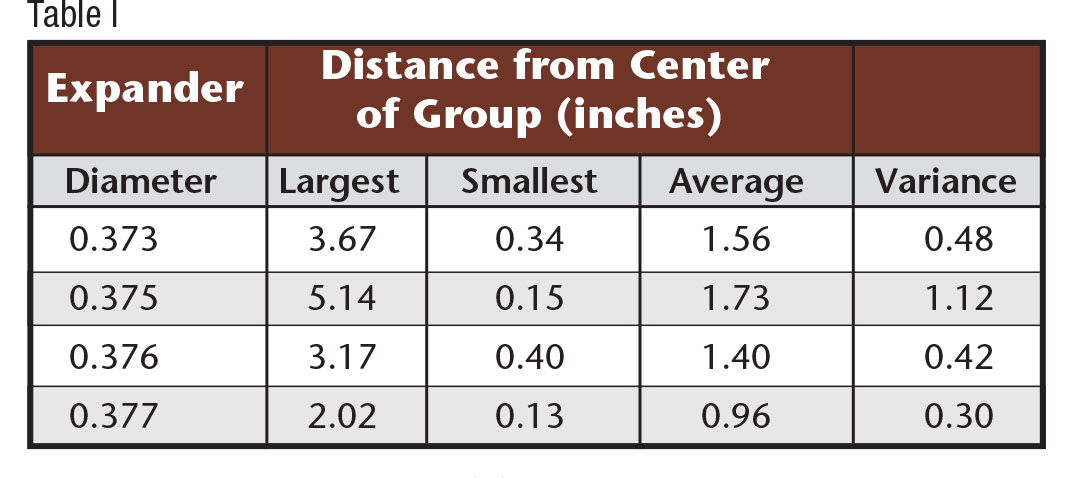

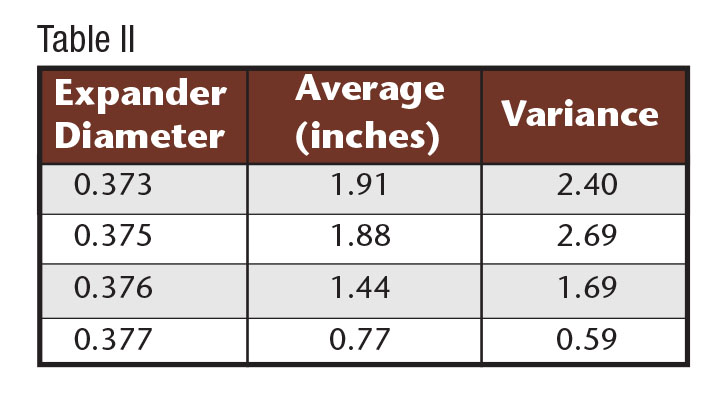

After all of the shooting, I ended up with a data set containing 35 measurements from the center of each group for each expander diameter. My hypothesis was there will be no difference in accuracy by using the four different expanders, .373, .375, .376 and .377 inch (null hypothesis). Completing an Analysis Of Variance (ANOVA), it can be stated with greater than 99 percent confidence, that there is a difference in accuracy between the four tests, Table I presents a summary of the results.

CONCLUSIONS

Using the .377 expander with the .376 Money bullet resulted in minimal bullet tension and yet, still required a reloading press to seat the bullets. Immediately after seating, a small percentage of the bullets could be spun using finger pressure. The following day, no bullets could be spun without significant finger pressure. I assume the brass relaxed? During reloading, I was concerned about this minimal tension and felt the perceived inconsistency would not result in great accuracy. It turns out it was the most consistently accurate.

I am not certain why the very light neck tension works so well in my rifle. Perhaps greater neck tension reduces the diameter of the lead bullet or distorts the bullet? Maybe the light neck tension holds the bullet just enough to keep it properly aligned with the rifle chamber? Not knowing the exact mechanism for the accuracy improvement was not as important to me as the outcome.

I am very pleased with the test results and analysis. It is certainly easier to fire one or two, five-shot groups and draw some conclusions. However, if the test is not repeatable, or better yet, statistically significant, it is anecdotal at best; an anecdotal test usually with cognitive bias.

REFERENCES

1 T.J. Napier-Munn pg.157

T.J. Napier – Munn, Statistical Methods for Mineral Engineers – How to design Experiments and Analyse Data. Julius Kruttschnitt Mineral Research Centre, Queensland, Australia, 2014

Hatcher, Julian S., Hatchers Notebook, Firearms Classic Library, Published for the National Rifle Association, Odysseus Editions, Inc, 1996

J.S. and Pat Wolf, Loading Cartridges for the Original .45-70 Springfield Rifle and Carbine, 2nd Edition, Published by Wolf’s Western Traders, Sheridan, Wyoming, 1996