SPG

Bullet Lubricants

feature By: Bob Glodt | December, 18

I’ve known Steve for over 20 years and have found him to be an accuracy fanatic and perfectionist when it comes to black powder cartridge rifle silhouette, Schuetzen competition, shooting muzzle loaders, as well as slug gun benchrest competition. He has a passion for any gun that was designed to shoot black powder and even some that were not. He once told me he was trying to figure out a way to disassemble .22 Long Rifle ammunition and substitute the smokeless powder that was contained within the commercially produced cartridges for black powder. Steve is pragmatic in his approach to diagnosing accuracy issues with rifles, eliminating one factor at a time until he gets to the root cause of inaccuracy. I have valued the friendship between Steve and I because he is always open to sharing his knowledge about shooting black powder cartridge rifles. To say that I have learned a lot from him would be an understatement. I also consider myself somewhat of an accuracy geek, albeit not to Steve’s level.

In the interest of transparency, it is important for readers to know that all opinions, comments and conclusions stated in this article are mine exclusively. I did, however, contact a couple of people who shoot competitively in the hotter and drier climates of the U.S. to get a better understanding of

how they deal with black powder fouling in extreme heat and low-humidity situations.

I asked Larry Baker why he was developing a new lube in the first place. He told me that some shooters who compete in the hotter and drier areas of the country felt like they got better performance from a lube that

I have used SPG Lube exclusively since I began shooting black powder cartridge rifle competition in 1987. I have never had an issue with the lube melting or not performing when a round was inserted into a hot chamber, or when SPG Lube was stored properly. Living in Texas, I have shot matches on days that were so hot that you couldn’t touch the barrel without burning your hand after a string of 15 shots had been fired. I have never had SPG Lube melt in the ammunition box or in the rifle’s chamber. So, to be perfectly honest about it, I never agreed with the assertion or assumption that SPG’s melting point was a problem in the first place. However, I applaud Larry Baker for his continued development of his product line. Larry also told me that the he and Steve collaborated in the development of SPG Tropic lube and 16 formulations were tested before settling on the one he now markets and sells as SPG Tropic. According to Larry, SPG Tropic is not intended to replace the original SPG lube, but rather to give shooters who compete in very hot and dry climates another option.

Shooters have preferences and opinions when it comes to loading black powder cartridge ammunition. Some prefer pan lubing while others use a lube sizer. I’ve tried pan lubing and I don’t much care for it. I didn’t say it isn’t a good way to lube bullets, I just prefer using a lube sizer because it is quicker and less messy. Also, lube does not separate from, or fall out of, the grease grooves when a lube sizer is used, as can be the case with pan lubing. I’ve tried to overcome this problem by heating bullets with a hair dryer before pouring melted lube in the pan with the bullets. Although heating bullets does help, it does not eliminate the problem.

[The problem that Bob speaks of comes from bullets not being the same temperature as the melted lubricant. If one leaves the heat source on the pan of lubricant while the bullets are placed in the pan, the bullets will come up to temperature in a few minutes. Doing this will allow the lube grooves to fill completely and prevent the lube from falling out when the bullets are pushed from the lubricant. –Ed.]

When using a lube sizer, I believe there are some common-sense guidelines that should be followed. The first of these is never oversize a bullet. My rule of thumb is not to size a bullet more than .0005 inch when using a sizer. I believe if the effect of sizing can be seen on the bullet, you are either sizing too much (the bullet is too big in the first place) or possibly the bullet mould is so out of round that it is unusable. The sizer dies I have on hand size a bullet about .001 inch smaller than the measurement stamped on the die, so the sizer die is selected by how much it actually sizes a bullet. My .459-inch sizer die sizes my .4585-inch diameter bullets exactly to .458 inch. Second, when sizing bullets, it is important not to

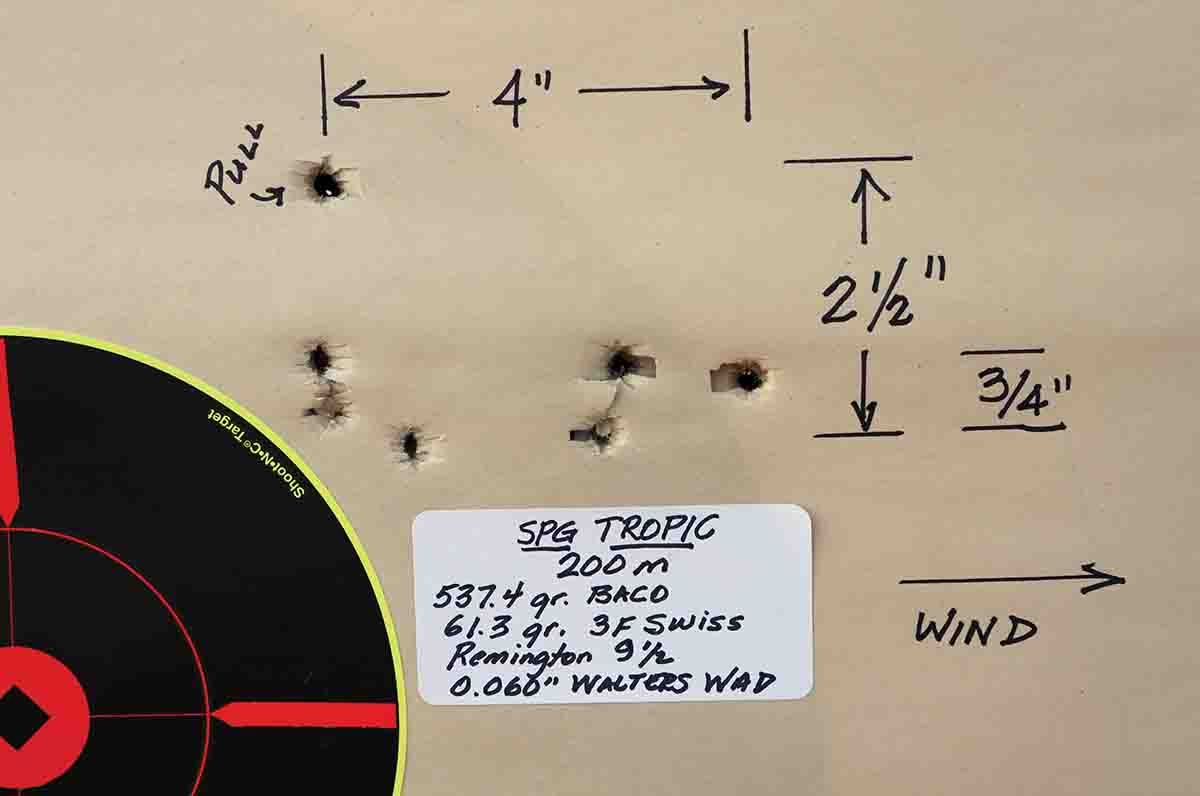

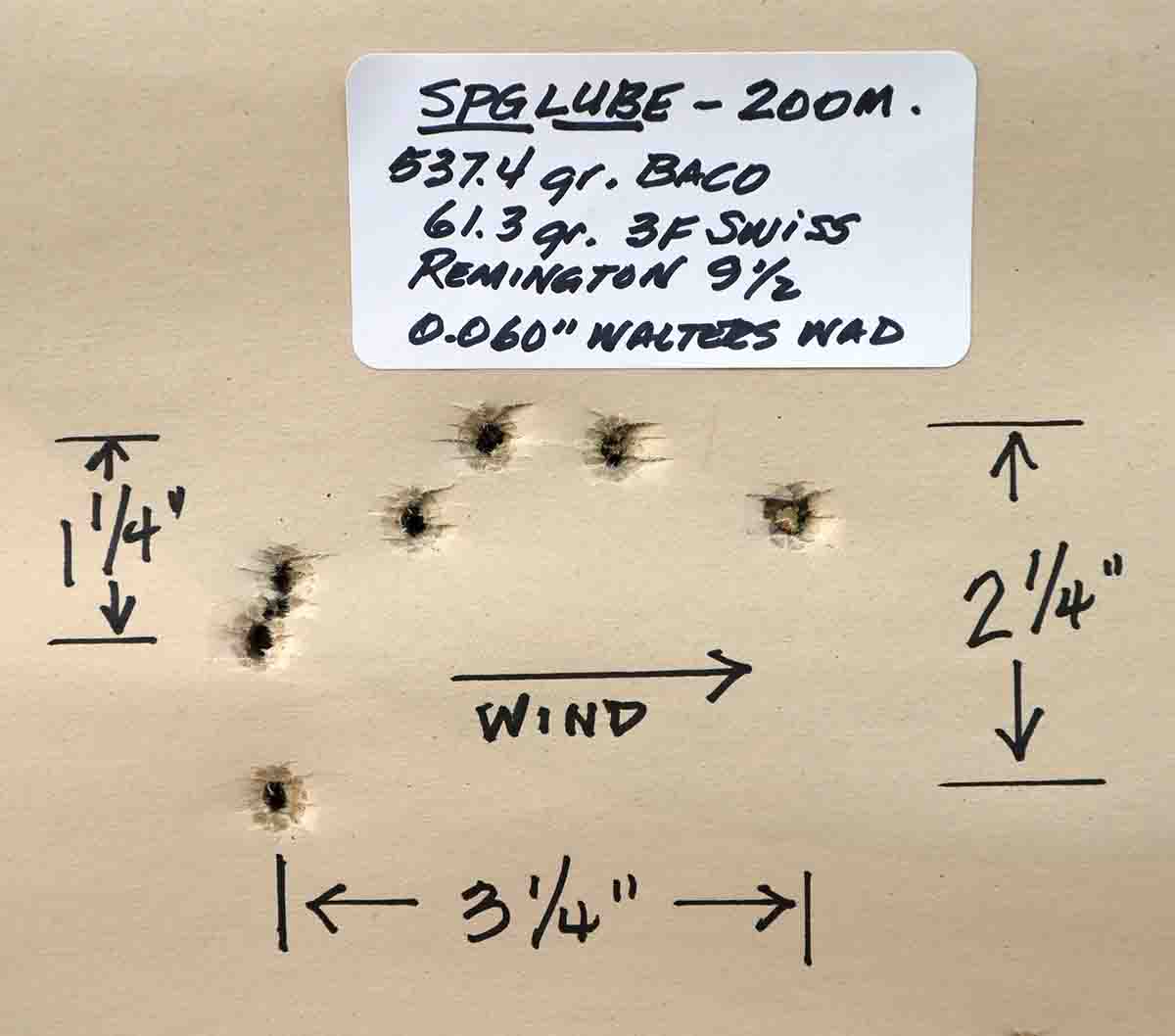

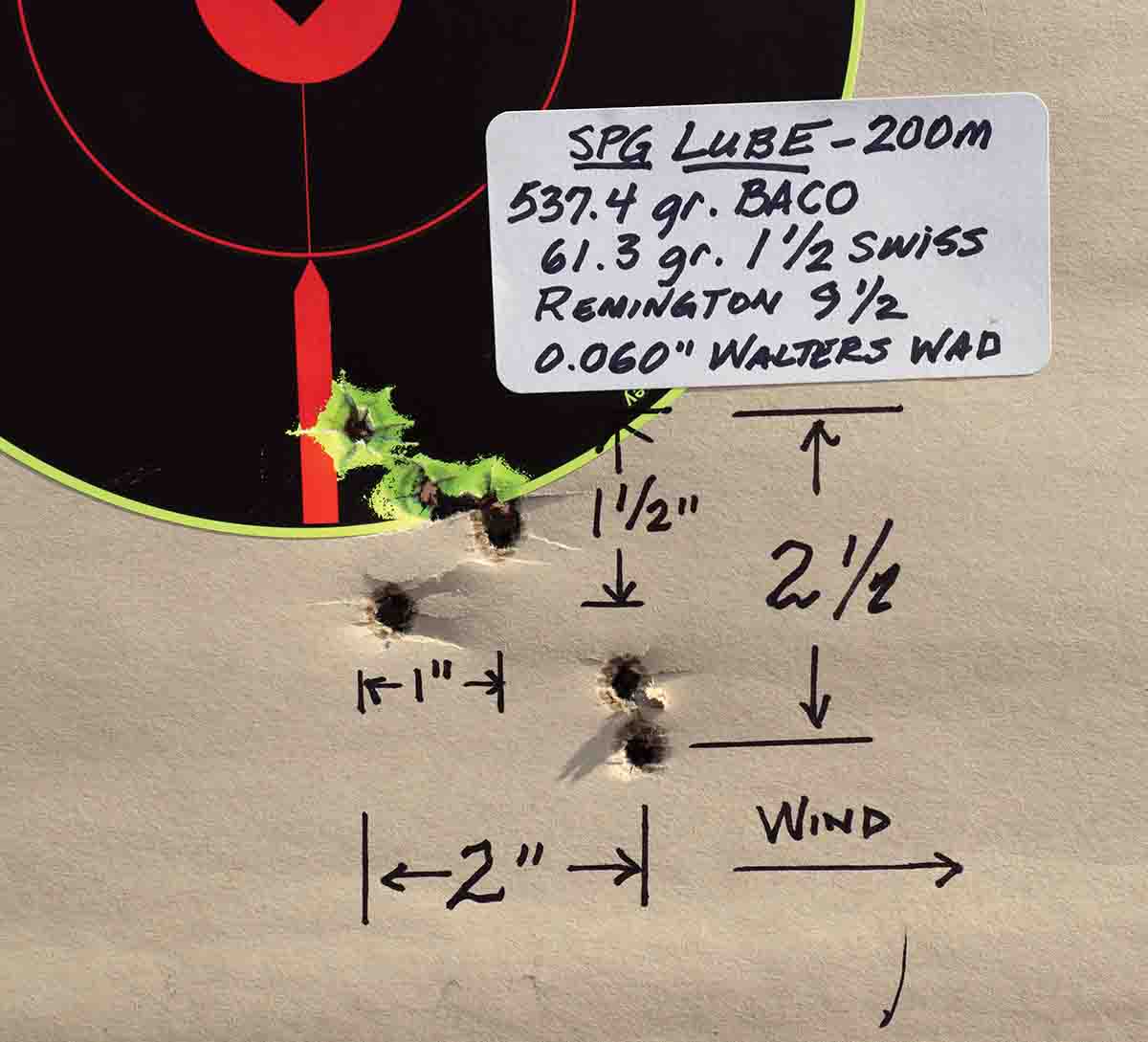

I received the SPG Tropic lube for testing on a Friday about four days before I was to leave for our monthly silhouette match. I had just enough time to cast bullets and load 15 rounds of SPG-lubed bullets and 15 rounds of SPG Tropic-lubed bullets. My standard load includes a four-grease grooved BACO No. 458540C3 bullet cast 25:1. The driving bands on this bullet all measure .4585 inch except for the top one which measures .451 inch. The bullet’s nose measures .448 inch. The top driving band and the top grease groove of the bullet are seated out of the cartridge case. This is done so the top driving band engages the rifling when the round is inserted in the chamber. All bullets used for test loads weighed between 537.3 to 537.4 grains. Annealed Starline .45-70 brass was used for both the SPG-lubed bullets and the SPG Tropic-lubed bullets. I have two Lyman 450 lube sizers, one was used for the SPG Lube and the other was used for the SPG Tropic-lubed bullets. The same .459-inch lube sizer die was used for both lubes. The sizer die was thoroughly cleaned to remove existing lube when I transferred it from one Lyman 450 lube sizer to the other. Remington 9½ primers were used. In addition, a newspaper wad was inserted in the cartridge case before the powder was poured into the case. The powder charge was 61.3 grains of Swiss FFFg and it was inserted into the case with the aid of a drop tube. A standard .060-inch Walters wad was placed over the powder and was seated to the proper depth using a compression die. This load requires a very slight amount of compression, and this compression was achieved with a compression die rather than with the bullet. All test loads had no more than .001 inch of total run-out.

For testing I had originally planned on shooting five fouling rounds off the target and the final 10 rounds on paper at 200 meters. As usual, operator error came into play, and I had scope issues that resulted in my only being able to fire seven rounds on paper for the first load. I therefore decided to shoot only seven rounds on paper for the second load, as well. I was disappointed that I didn’t have more ammunition handy to shoot 10 rounds of each of the two test loads, but that is the way it was. The barrel was not cleaned or wiped between shots while shooting for group. However, I did use a blow tube to blow three long breaths into the barrel between each shot. Between firing the SPG and the SPG Tropic bullets, the rifle was cleaned and allowed to cool out of direct sunlight. Allowing the rifle to cool between relays is my normal procedure when shooting a match. After firing the first five fouling shots, the barrel

A Shiloh Sharps rifle .45-70 with a 32-inch barrel was used for testing.The barrel has a 1:16 twist and is a standard-weight octagonal barrel rather than a heavy full-octagon. A 23-inch MVA 8X scope was also mounted on the barrel.

The SPG Tropic lube load was fired first. The seven shots went into a group 2½ inches tall by 4 inches wide. The bullet that is “out of the group” was my second shot. A light wind was blowing from 9 o’clock to 3 o’clock, which accounts for the horizontal spread. I made no attempt to adjust sights for changing wind conditions when firing either SPG-lubed loads or SPG Tropic-lubed loads. If you throw out the one shot that was out of the group, the group measures ¾ inch tall by 4 inches wide.

The SPG-lubed loads were fired second. The seven shots went into a group that was 21⁄4 inches tall by 31⁄4 inches wide. As with the SPG Tropic, I did have one round out of the group. This was the fourth round fired on target. As with SPG Tropic, wind conditions were blowing from 9 o’clock to 3 o’clock. If the one round out of the group was eliminated, the vertical spread for this load was 1¼ inches.

Although I originally had not planned to include other load testing for a comparison in the article, I decided to include a seven-shot group with SPG-lubed bullets and 1½ Fg Swiss powder. Since I am getting a little low on Swiss FFFg powder, I was curious if 1½ Fg Swiss, (of which I have plenty) would perform as well as the FFFg Swiss in the rifle. It was the following day when this group was tested and the temperature was 73 degrees. From the photo, it appears that there are only six rounds in this group; however, two shots were a double. The group measured 2½ inches by 2 inches, or close to one minute of angle, when calculating for a distance of 200 meters.

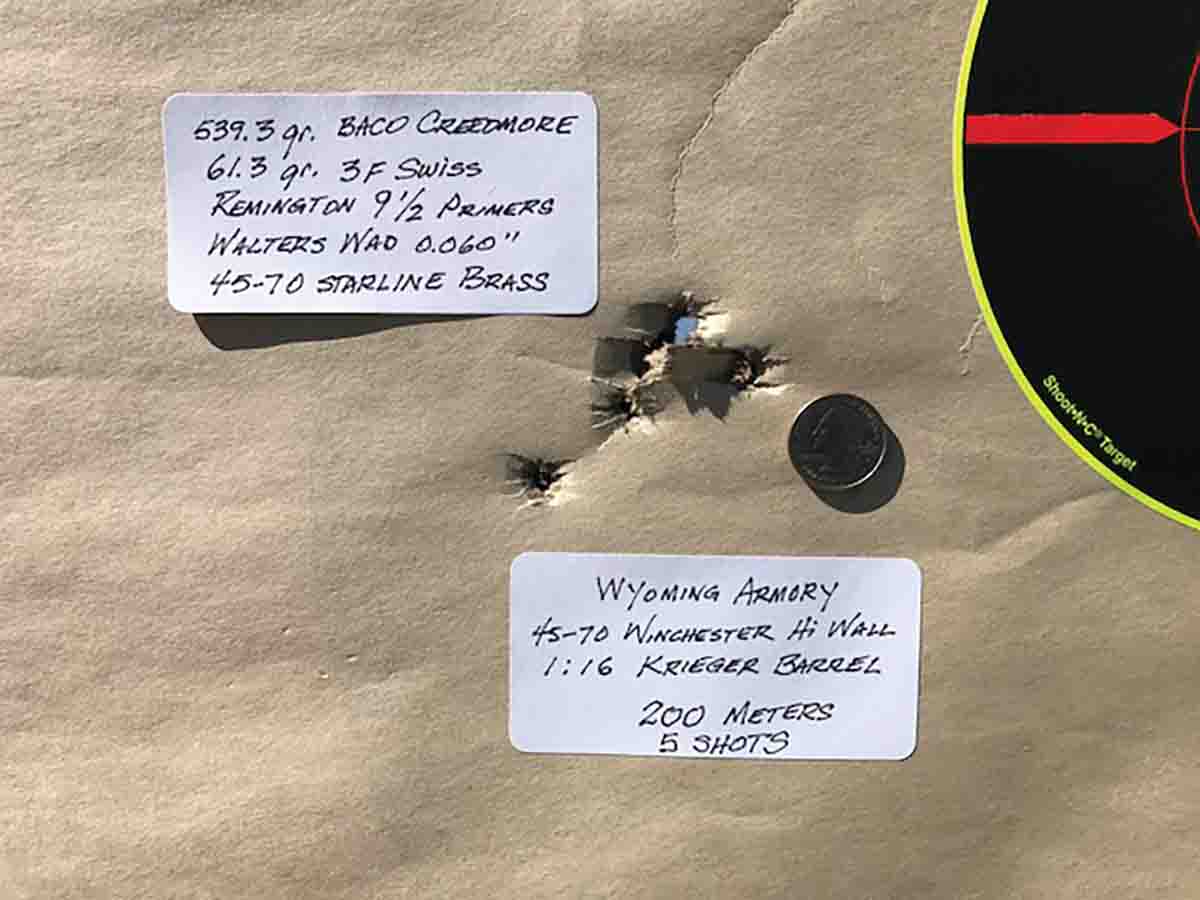

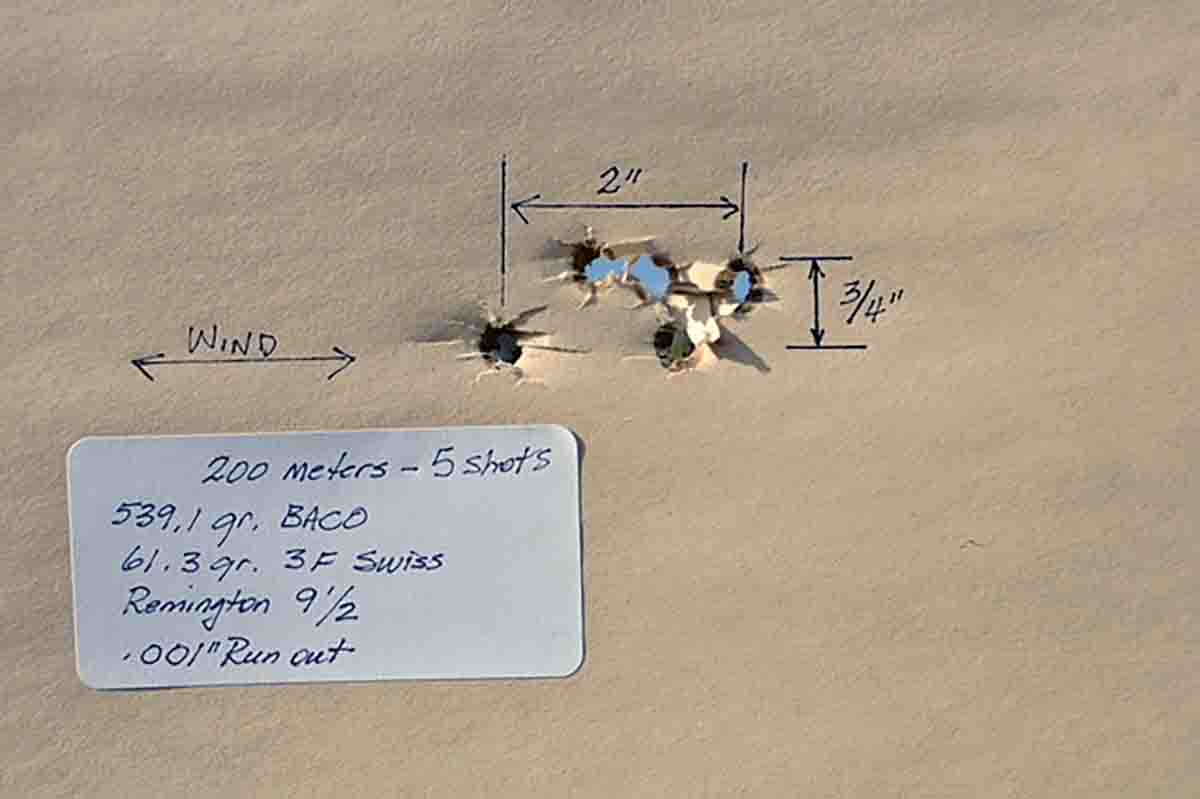

The groups I fired with SPG original and SPG Tropic were decent; however, I have included two other five-shot groups that were fired with two different rifles for other articles I have written. SPG original lube was used for each of the two groups. One rifle used was the Shiloh shown in this article, and the other group was shot using a Wyoming Armory High Wall rifle that is equipped with a 1:16 Krieger barrel. I have included these photos for no other reason than to show the accuracy potential of good ammunition in combination with an accurate rifle. This level of accuracy would not be possible if SPG Lube did not perform exceedingly well.

So, what does all of this data mean? From the limited testing I conducted, both lubes performed extremely well. I personally prefer the standard SPG Lube because it is softer than SPG Tropic and with years of shooting experience with the standard SPG Lube, I trust it to perform well in all shooting environments that are common to my shooting regimen. When I say perform it means my barrel does not lead, fouling remains soft from one shot to the next (when a blow tube is used), and I always get a soft grease “cookie” on the muzzle of the barrel after a string of fire. But more importantly, the loads will consistently shoot a minute of angle and even better when I’m steady on the gun. However, I never doubt the experiences of others who may shoot in entirely different conditions than I do. The SPG Tropic lube may very well improve accuracy for those who regularly compete in extreme heat and low humidity.

Now, I would like to discuss the issues of lube, blow tubing, and wiping between shots in more detail. As previously mentioned, the silhouette rifle is a Shiloh Sharps with a 32-inch, 1:16 twist, standard-weight barrel. If barrel fouling was ever to be a problem, it would seem I would have it. One compromise I have had to make with a faster twist .45-caliber barrel is that it takes more sighter shots from a clean barrel for rounds to “settle in” and shoot a group. For over five years now, it has become my standard practice never to clean or wipe the bore of the barrel between relays, no matter how hot it is. I essentially shoot “dirty” the whole match. I clean before the first relay and after the last. I know what you are thinking, He probably doesn’t shoot all that good anyway. I can honestly say, “The only targets I miss are the ones I don’t hit.” Seriously, the rifle performs exceptionally well in this scenario and I have never felt I have lost targets because of barrel fouling. When starting a new relay with a dirty barrel, my second sighter round is right in the group. Being 100 percent confident that my rifle is shooting a group before going for score is a strong advantage in silhouette competition.

So, how is it that I can maintain accuracy for an entire match without cleaning between relays? If you think about it, every round that is fired pushes the fouling from the previous shot out of the barrel and deposits fouling from the last shot fired. I have looked down the barrel between relays and an accumulation of fouling from the first relay to the last can’t be found. After all, it takes no more cleaning patches to clean my barrel squeaky clean after shooting “dirty” an entire match than it does cleaning between relays. This technique works for me for three reasons: First, as long as a blow tube is used between each shot, SPG lube does a phenomenal job of keeping the fouling soft. Second, FFFg Swiss powder burns very clean. Finally, I produce a lot of moisture in my breath and can always see moisture in the clear plastic blow tube when blowing between shots. I fully realize that I am in the minority when it comes to shooting dirty because most competitors clean their barrel between relays. And, there may be good reasons why these competitors choose to clean between relays. However, being able to shoot dirty for an entire match without loss of accuracy is a strong testimony to how well SPG lube performs.

I know there are many excellent black powder cartridge riflemen who wipe between shots and achieve excellent results from doing so. I’ve tried it and have had good results, but the accuracy I have achieved is no better than shooting dirty and blow tubing. And for someone who is prone to operator error, adding a wiping operation between each shot in a relay would be a problem. I have told my wife if I were a woman, I could never get a bra on without it being all twisted up. I can only imagine the assortment of problems I would have trying to wipe the barrel after each shot. So, if someone has good luck wiping between shots and can manage the technique in the time constraints of a relay, they should just keep on wiping.

A quality lube will keep powder fouling soft, minimize leading (in a good barrel), and is important in achieving consistently accurate groups. I can say without hesitation that SPG lube has been a consistent performer in the many different rifles (and barrels) I have competed with, in several different calibers, and in different environmental conditions. The SPG line of lubes are very economically priced. It takes 2.8 grains of SPG original lube or SPG Tropic to lube my four-grease groove .45-caliber bullet. At a cost of $32 for a one-pound block of SPG Lube and $35 per pound of SPG Tropic, that equates to a cost of roughly 77 cents and 84 cents, respectively, to shoot a 40-round match. And, this assumes five sighter rounds will be shot at each bank of targets before going to score or a total of 60 rounds. For that price, why would anyone would want to go to the trouble of trying to make their own bullet lube? So, when going through life, just remember “Cokes explode.”