Product Reviews

whatsnew By: Staff | February, 20

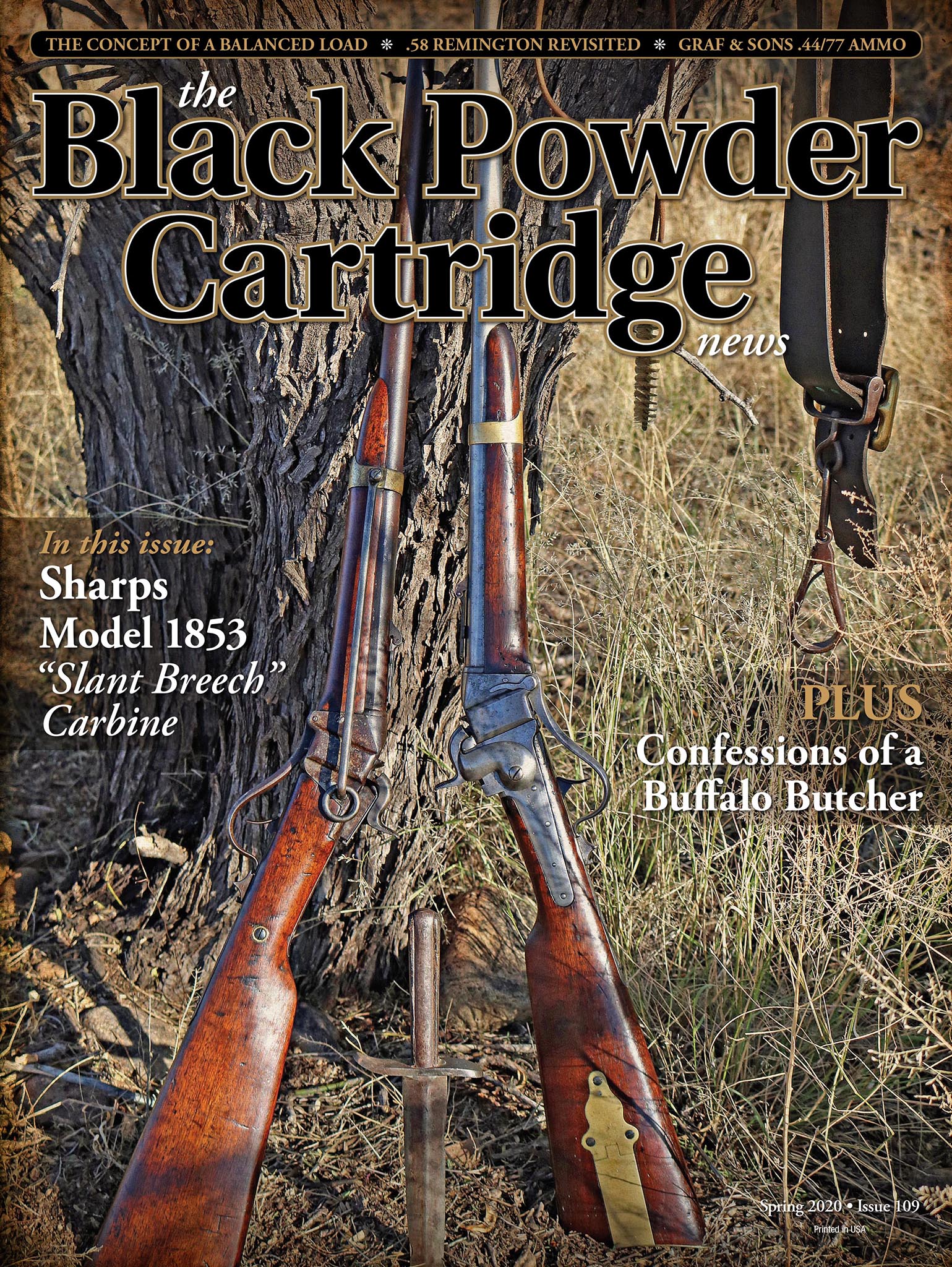

.44/77 Ammunition from Graf & Sons

Graf & Sons is a well-known ammunition and reloading dealer located in Mexico, Missouri. They often have ammunition for hard-to-get calibers. They also stock and sell black powder. For some of the cartridges, they will sometimes place a big order with an ammunition producer and then buy the entire order, so they are the exclusive supplier of that particular ammunition. That’s just what they did with these .44/77 rounds by Precision Cartridge Inc.

I noticed this ammunition while stumbling across a list of calibers for “Rifle Ammunition” on Graf & Sons’ website. It was a surprise to see .44/77 ammunition listed even with one loading. That, of course, made me wonder what they were using for brass, especially because the .44/77 is not included in their brass list. A note was sent asking who the maker of their brass is and a rapid reply told me it was Jamison. That’s when I really started paying attention.

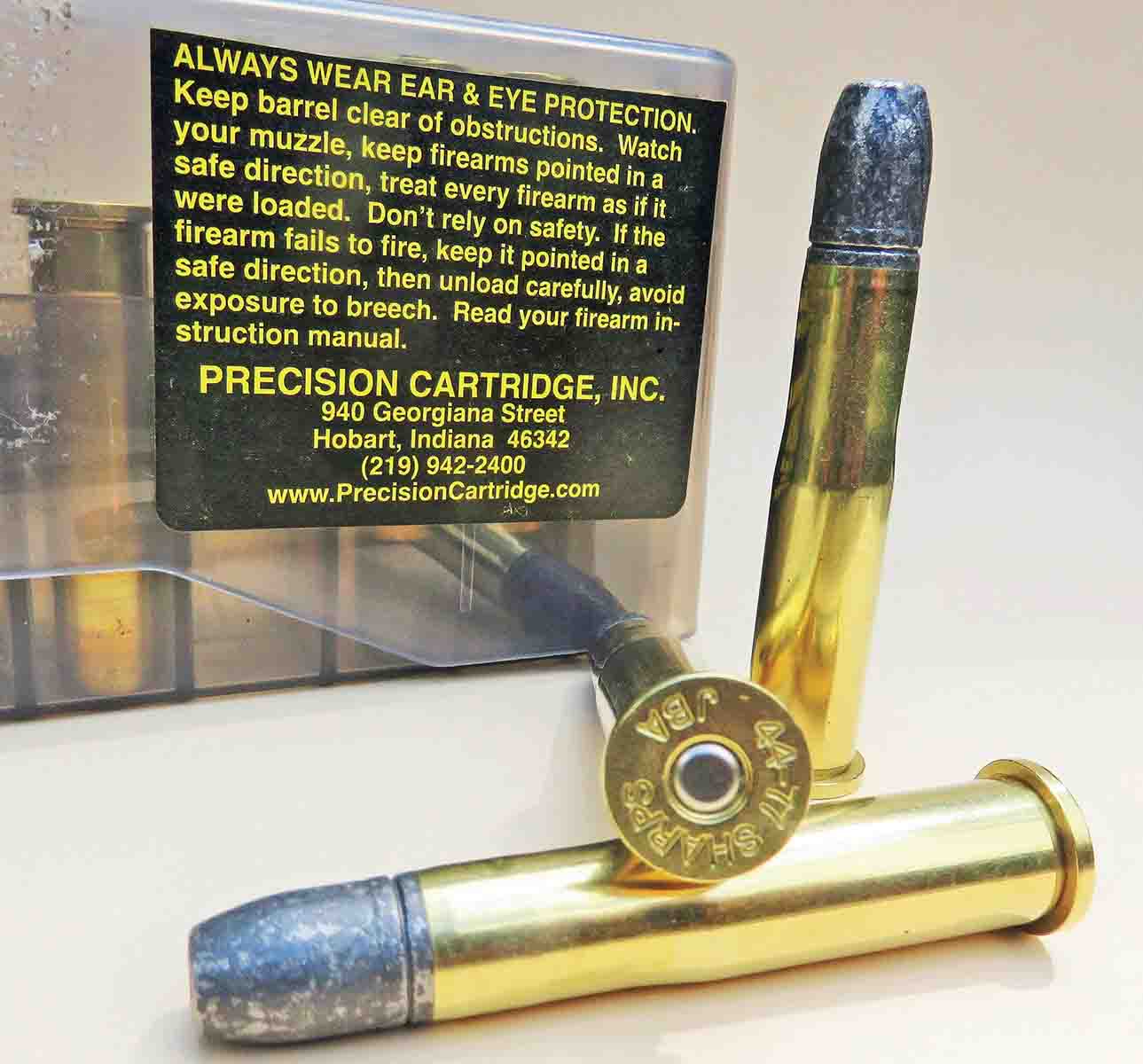

The only specific information about these .44/77 cartridges they provided was that the ammunition used a 365-grain lead bullet and their price for a box of 20 cartridges was $62.99. To answer any more questions, I would need a box of ammunition, so one box was ordered.

That order was received very quickly. There they were, 20 rounds of brand new shiny .44/77s held in a plastic Case-Gard cartridge box. They did look good and the brass was certainly made by Jamison, marked with their last headstamp which read “44-77 Sharps” over “JBA.” I was delighted to have more Jamison .44/77 brass.

The bullet Precision Cartridge Inc. used was immediately recognized as .44-385 by RCBS. In order to check things thoroughly one of those bullets was pulled and it certainly was the RCBS bullet. With soft lead that bullet usually weighs about 405 grains. I’m just guessing that the folks at Precision didn’t weigh the bullets and expected their bullets to weigh less than RCBS’s advertised weight of 385 grains because they were using a harder alloy. That guess is backed up by an experienced thumbnail test and the bullets are harder than the 25:1 alloy that I generally use. The pulled bullet was weighed at 397.5 grains.

These lead bullets are not lubricated with any grease in the grooves. Instead they are covered with a coating that I cannot identify. I wondered how these bullets would perform with no grease in the grooves, but they shot rather well, and these are smokeless powder loads. The bullets were seated into the case and crimped into the top lube groove instead of the rather small crimp groove just a little higher on the side of the bullet. That made chambering these cartridges on the difficult side in my C. Sharps Arms .44/77 rifle. A chambering cam was used each time a cartridge was put into the chamber, forcing the nose of the bullet into the rifling.

The powder is another part of the load that I can’t identify, about 37.5 grains of a cylindrical smokeless powder. It most likely is A-5744 but that is a complete guess on my part. Shooting this ammunition proved to be quite enjoyable. No high-pressure signs were noticed, such as hard to extract cases or flattened primers. To check the bullet’s speed, one shot was fired over the chronograph and that gave a velocity of 1,405 feet per second.

Shooting was done on a windy day and that didn’t help the group size. The target was suspended on two small rope lines, somewhat like clothes lines, and the target kept “dancing” in the breeze. Even so, the group still satisfies me. Five shots were fired with my rifle’s sight set for my favorite black powder load and you can see the resulting group on the 100-yard target. That for sure would have put meat in the pot.

Plinking with this smokeless ammunition was fun but the very best part of it was the nicely fireformed Jamison brass that is now ready for reloading with black powder. Before writing this review, contact was made with Graf & Sons again to see how much of it they had. I was told they had 50 boxes ready to go. And to let you know what I really think of this .44/77 ammunition with the Jamison brass, I ordered five more boxes of it for myself. To check on the availability of this ammunition or to place an order, go to Graf & Sons at grafs.com. Contact information: 4050 S. Clark, Mexico MO 65265; customer service/orders: 1-800-531-2666; phone: (573)-581-2875 or fax orders: 1-800-367-7626; technical assistance: (573) 581-2266. - Mike Nesbitt

Revolver Grips from the Gripmaker

This review should be started by telling you how much I like the old Smith & Wesson Model No. 3, the finest single-action, top-break revolver ever made. That really wouldn’t say much about the revolver grips being reviewed, but it would give you an idea about why this subject came to mind. My gun is actually a Beretta “Laramie” in .38 Special, a very fine copy of the old S&W. I wanted my gun to be somewhat personalized and these new grips did that with a nice touch.

Ivory grips on a sixgun have always appealed to me. That was just one of the things that led me to buy from the Gripmaker because their grips are made with a durable urethane, which can age (and yellow) like ivory. Each set of grips comes with the screw and escutcheons plus a brief but detailed set of instructions on how to fit the grips. In those instructions, there are hints about how to “age” your grips with dyes and even how to make artificial cracks to add to the aged look. I figured to “age” my gun’s grips the natural way, and that will take some time.

The Gripmaker also offers sculpted or “carved” grips featuring snakes, steer’s heads, the Texas star, buffalo skulls, and other designs too numerous to mention. Those designs, however, are not available for all styles of revolvers, and for my S&W-styled gun, my only choices were plain ivory or stag.

Fitting those grips took a little bit of time. The fitting began at the top, in the half circle where the top of the grip meets the revolver’s frame. The grips were oversize to begin with and a little “inletting black” was applied to the revolver’s frame to show where the material needed to be removed. Then those black marks were removed with a file, slowly working and checking the fit over and over until the fitting was done.

Then the grips were marked around the gun’s grip frame so the excess “ivory” could be removed from those areas. That work went faster than expected. Once the grips were basically fit, and I mean just brought down to size, the holes for the indexing pin through the grip frame were drilled. One of those had “traveled” on me and needed to be filled, then drilled again. That’s also when the escutcheons are inserted into the outside holes on the grips and the grips are screwed on to the sixgun so the grip screw can be shortened.

Next the grips were removed again and sanded to take away any file markings as well as to smooth the contours of the grips. I thought about going further, sanding more with some much finer sandpaper. But that’s when I thought I could hear my dear ol’ Dad’s words saying, “You know, you don’t want your sixgun’s grips to be slicker’n snot on a glass doorknob! You might need to hang on to it!” That’s when I quit sanding.

Now my .38 is wearing its “ivory” grips and doing very well with them. That sixgun might become a real partner at various times, riding in its cross draw holster. Those grips have gotten dirty, been wiped clean, handled with both cold and sweaty hands, and done all kinds of things that might add to their aged look. I’m in no hurry, but that aged look is coming.

These grips from the Gripmaker please me very well. I can also say that the customer service from the Gripmaker pleases me just as much. They’re very good people to deal with. If you are a first-time customer with them, just check the appropriate box on their order form and they’ll include a free extra grip for you to practice your fitting with. They offer grips in either the one-piece or two-piece configurations. On the sculpted designs, the grips are made so the grip screw does not go all the way through. And if you have a sixgun with an odd shaped grip, they ask for a tracing to see if they have anything that might fit.

Prices are very reasonable. The plain “ivory” grips that I got for my .38 were just $45. Natural stag designs begin at $65. There are other options with varying prices, and it is best to look at their wide list of grip styles for their availability. While I’ve only mentioned revolvers, they also offer grips for the 1911 Colt.

The quickest way to see more about these revolver grips is to look at their website by going to gripmaker.com. Contact information: Gripmaker, 17401 State Hwy 96, Carthage MO 64836; phone: 417-359-8880 or email: gripmaker@suddenlink.net. - Mike Nesbitt

Lee Classic Single Stage Press

While in New Zealand, I needed to upgrade my reloading capabilities from a simple hand-held compact press to a full-size single stage press. I decided to give the Lee Precision, Inc. “Classic Cast” single stage press a try. Several reviews on the various Internet reloading forums spoke glowingly of the Lee press and when it arrived, I was immediately impressed as well.

It’s solid and heavy, and being made from steel castings and machined fittings, there was no doubt in my mind that this “O” design press was up to heavy-duty sizing of the largest of cartridge cases. In fact, the Lee Classic press can be set up to reload .50 BMG ammunition. There’s over four inches of opening which easily accommodated the cases from my .577/.450 Martini. The lever works very smoothly and the 1 1⁄8” ram has no play, sliding easily in the machined frame-hole. The compound linkages are well-finished and closely fit; the whole unit just works precisely and with no wobble or slop. I especially like the adjustable handle, which can be set up for right- or left-handed operation and set for the amount of pitch as well. The Lee Classic press comes with two primer arms, one for Small Rifle primers and the other for Large Rifle. There’s also a spent primer tube that captures ejected primers and keeps them from scattering on the shop floor.

I mounted the Lee Classic on my reloading bench and proceeded to size and reload some .577/.450 Martini cartridges. Full-length sizing was extremely easy, almost effortless given the compound linkage system. The large opening was very handy; no angling of cases with started bullets to line up with the dies.

After loading 50 of the big .577/.450’s I was ready to pronounce the Lee Classic a success. At a suggested retail of $190.00, it is not the cheapest single stage press around, but I think it represents great value, especially to the reloader who wants quality equipment right from the start. I don’t think it is a stretch to say that, with proper care, the Lee Classic press would last more than a lifetime of reloading.

Lee Precision, Inc. makes a complete line of reloading tools and dies, as well as bullet moulds and casting equipment. I was impressed with their products. View all their reloading products at their website leeprecision.com. Contact information: 4275 County Road U, Hartford WI 53027; phone (262)-673-3075 or fax (262)-673-9273. - Steve Garbe