Greenhill, With a Twist

other By: Steve Garbe | December, 25

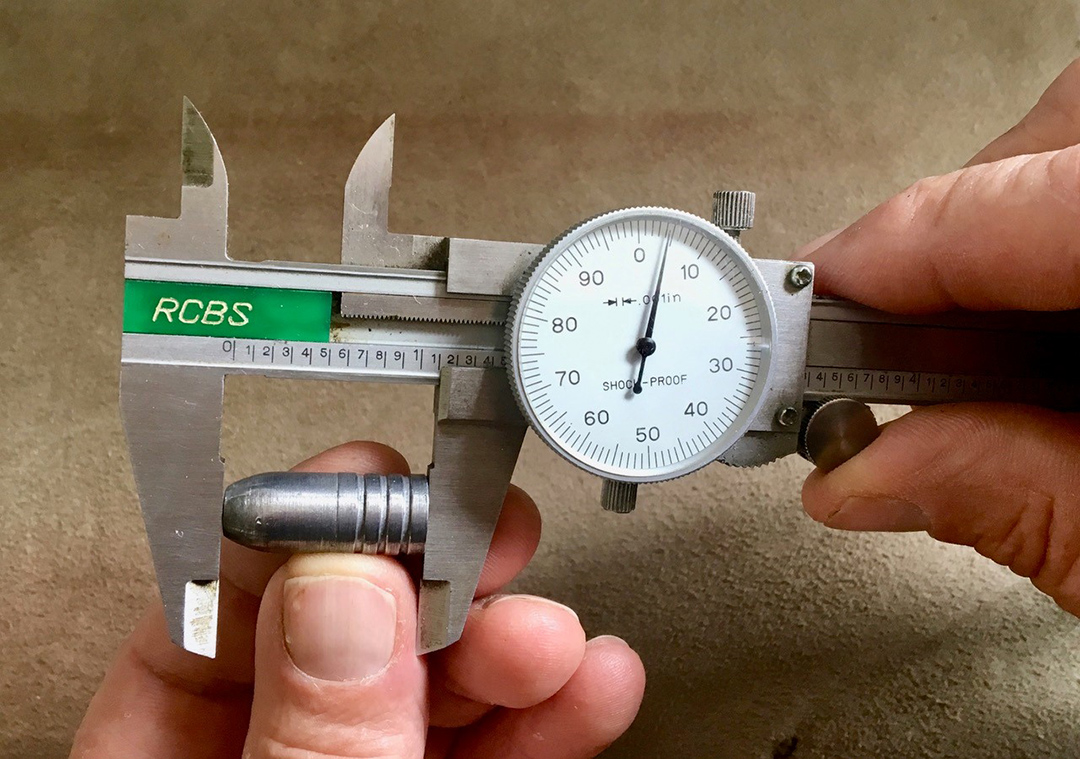

An example for a .38 (.375 inch) bullet that is 1.4 inches long would be:

1.4 divided by .375 equals 3.733, 150 divided by 3.733 equals 40.182 and 40.182 times .375 equals 15.068. The number 15.068 is then the minimum barrel twist-rate required to stabilize that particular bullet.

As much as I respect Greenhill, I have, however, adopted a variation of his formula based on my own shooting over the years. I observed that for ranges beyond 200 yards, one is better served to tighten the calculated twist by at least one inch. Hence, the new modified answer would be 14.068 or, practically speaking, a 1:14 twist.

I think the reason behind my adaptation to the original formula was necessitated by the fact that the Greenhill calculation was reportedly based on a 1450 feet per second (fps) bullet muzzle velocity. Our typical black-powder cartridge rifles generally run at about 1,150 to 1,250 fps. This velocity gives a slower rotational velocity to the bullet and in my own experience requires a slightly faster twist for best results. I had noticed better accuracy when using slightly shorter bullets than what was used to calculate the recommended twist. A long, heavy bullet would also respond favorably to increased velocity, sometimes as little as 50 fps. Bullet prints on the target easily showed the increased stability with the holes cut by the bullet’s nose well centered in the overall hole. A heavier grade of paper or cardboard will show the rifleman well-defined bullet prints to judge bullet stability from.

Tightening a twist does come with trade-offs. Increased torque is the main negative, and torque is the hardest part of recoil to deal with consistently, shot to shot. Also, tightened twists will sometimes require slightly harder alloy to prevent bullet stripping. However, I personally think that too much has been made of the “excessive twist” argument when short bullets are fired in barrels set up for long projectiles. I regularly shoot short, 330-grain .45-caliber bullets in barrels with 18-inch twists and enjoy exceptional accuracy.

The current trend in BPCR competition is towards tighter twists in many calibers. I’ve heard of a number of riflemen using 1:16 twists in .45-caliber rifles, 1:14 in the .40’s as well as twists as tight as 1:12 with various .38-caliber cartridges. It would seem that many practical shooters have noticed the advantage of tightening up Sir Alfred’s time-honored formula to better fit with modern-day black-powder cartridge shooting scenarios.

In summary, I would say that tightening a twist by at least one inch over the Greenhill recommendation surely cannot hurt and many times helps increase accuracy, especially at longer ranges. I also believe it is better to err on the side of overstabilization than to risk losing ballistic coefficient due to a tipping bullet. In calm conditions, a slightly tipping bullet can often show remarkable accuracy, but introduce some serious crosswinds and that same bullet/twist combination will become very erratic. This is not something you want to find out during a big match when the goal is the best possible score.